Concept.

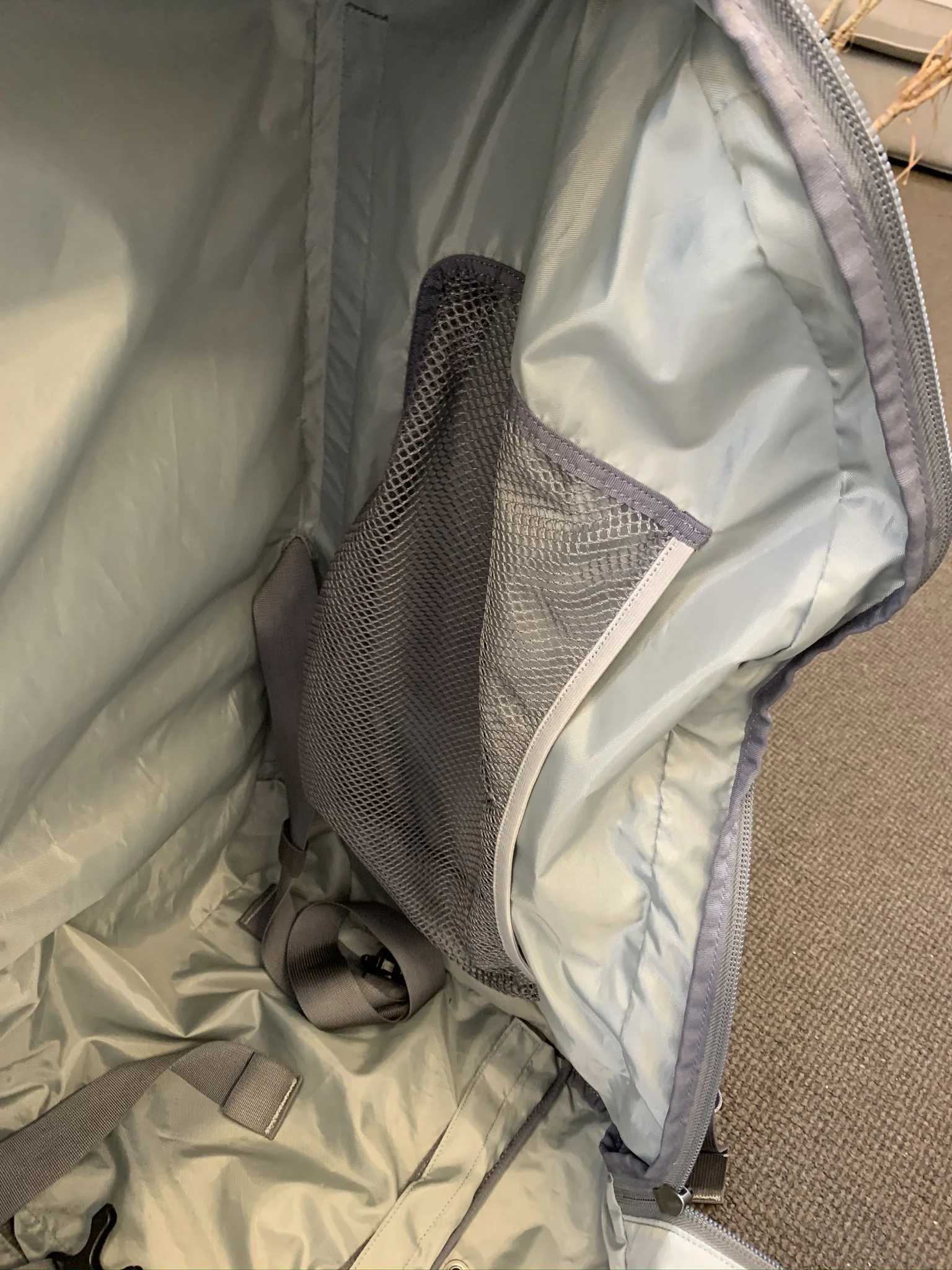

The bag was designed to securely store the kayak when deflated. All the components needed on the kayak could be stored safely in the bag as well. The bag would feature a semi-rigid back to give structure. Wheels and a telescoping handle add functionality. I held responsibility for the design of all bags.

Prototypes.

Bag sizes were verified with full-scale 2D profile prints on paper. Once sizes were confirmed, the bag designs were sent out to our soft-goods vendor for pattern-making and sampling. The first-round prototype of each bag was made while visiting the vendor.

Samples.

Four rounds of samples were made for the iTrek bag line. Hull samples were sent to the bag vendor for fit verification. Two vendor visits were critical in the development and finish of the bags. High-quality wheels and telescoping handles were sourced from third-party vendors. I handled sourcing and coordination of the bag development. Test samples were used for two years, locally and internationally.

Production.

Our vendor met the delivery date for the first and second PO. The third and fourth PO was delayed by Covid-19 due to a limited workforce at the factory. Production units met and continue to exceed the quality expected.

-

Hull

-

Seat

-

Steering

-

Interface

-

Industrial Design